When extruding, it's important to control a process and make adjustments within certain limits. It's a continuous process where semi-finished products are formed such as tubes, sheets, films, profiles, or rod material, and there is no opportunity for extensive measurement and testing in between. During the Extrusion 1 course, you will learn the basic knowledge to keep the process running and make minor parameter adjustments.

- Learn the key properties for processing thermoplastics and thermoplastic elastomers

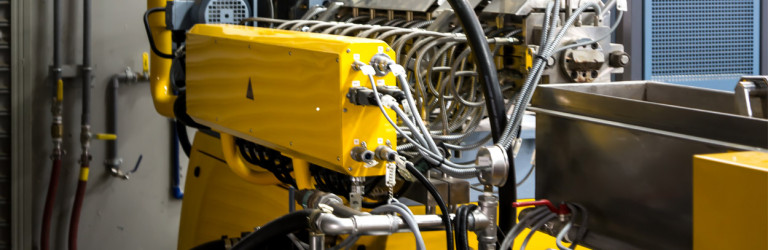

- Learn the structure, components, and operation of the extruder

- Learn the operation and influence of various parameters

About the Extrusion 1 course

The extrusion processing technique may seem simple, but appearances can be deceptive. The Extrusion 1 course not only covers the basic knowledge but also briefly discusses the differences in the follow-up lines. To understand the extrusion process well, basic knowledge of plastics is essential. Additionally, it's crucial to know the parameters of the entire extrusion line and their influence.

The Extrusion 1 course also addresses safety and quality aspects surrounding the extrusion process. The theory is supported in a fun and practical manner through numerous product examples.

Program

Product Knowledge

- Classification of plastics

- Identifying plastics

- Material properties of the main thermoplastics

- Material properties of the main thermoplastic elastomers (TPE)

- Processing aspects

- Output of the extrusion process (calculating throughput, volume, kg per hour)

Safety

- Safety in plastic processing

- Safe working practices

Environment and Product

- Recycling and reuse of plastics

- Efficient use of energy

Quality Management

- Quality system

- Production control

- Troubleshooting common issues

- Documentation, reporting, and communication

Equipment Knowledge

- Operation of the extruder

- Different extrusion processes (single screw, twin screw, conical)

- Construction of the single screw extruder

- Screw geometry

- Different follow-up lines (tube, rod, sheet, film, foil, co-extrusion)

- The extrusion die

- Using and assembling the extrusion die

- Material feeding

- Auxiliary equipment (dryers, colorants, mixers)

Discover the possibilities to organize this workshop internally within your company

When you want to train multiple employees in your company, it is more interesting and cost-effective to organize a course at your location. Good alignment with your company-specific situation and the use of highly experienced instructors who have earned their stripes in practice is essential here. Mikrocentrum is CEDEO-certified and guarantees the best quality.

Our program manager is happy to think along with you!

Are you interested in this in-company trajectory? Our program manager, Barend Blom, would be happy to visit you without obligation.