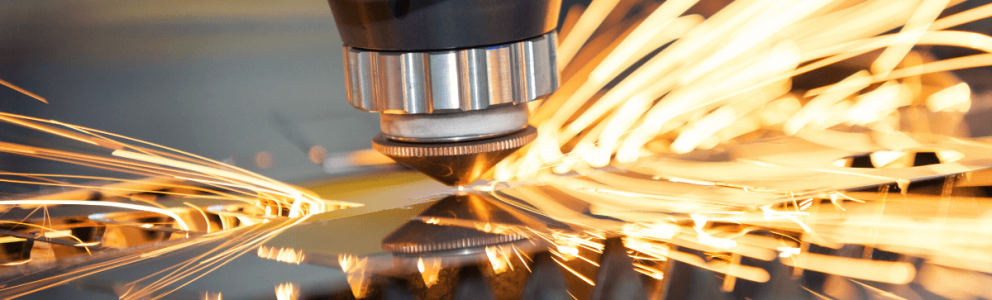

Laser welding is a specialism in which laser knowledge and skills are essential to achieve a desired end result. During this unique Laser Welding course, you will learn to weld safely with lasers through an ideal mix of theory and practice.

- Gain a complete picture of the possibilities the laser welding process can offer

- Learn how to safely apply laser welding in practice

- Understand the operation of a laser with its possibilities and impossibilities

About the course Laser welding in practice

Laser welding is a specialised field in which laser knowledge and skills are essential to achieve a desired end result. How do you get sufficient knowledge in this field in a short time?

Experience laser technology by doing it yourself

During this unique Laser Welding course, you will learn how to work safely with lasers through an ideal mix of theory and practice. You will understand what is involved faster and better because the theory is directly applied in a practical setup, so you see what actually happens. At the end of the course, you will have a complete picture of the possibilities the laser welding process can offer. Because you will work with lasers yourself during the course, you will learn how to apply it safely in practice.

Program

The Laser

- Laser Operation

- Laser Properties

- Solid-State Lasers

- Diode Lasers

- CO2 Lasers

- Advantages and Disadvantages

Laser Welding

- Spot Welding

- Seam Welding (Pulse)

- Seam Welding (Heat Conduction)

- Seam Welding (Deep Penetration / Keyhole)

- Cladding

- Welding Plastics

Beam Control

- Laser Construction

- Fiber

- Optic Holder

- Spot Size

- Protective Glass

Laser Systems

- Spot Welding (Spot)

- Spot Welding (Seam)

- CW Welding (Solid-State)

- CW Welding (CO2)

Safety

- Theory

- Hazards

- Laser Safety

- Safety Solutions

Laser Welding Process

- Time

- Space

- Energy

- Material

Weld Quality

- Weld Pool Size

- Penetration Depth

- Weld Location

- Weld Strength

- Seam Tracking Systems

- In-line Control Systems

Selection and Purchase

- Selection

- Specification

- Purchase

- Investment Costs

- Operating Costs

- Installation

Practical Day

- Introduction to solid-state and CO2 lasers in a production environment

- Hands-on laser welding using a laboratory setup

- Direct experience with the influence of spot size, energy, pulse duration, weld location, material thicknesses, and properties

- Measuring laser energy and adjusting/changing various optical components yourself

Discover the possibilities to organize this course incompany

If you want to train several employees in your company, it is more interesting and cheaper to organize a course at your location. Good coordination to your company-specific situation and the deployment of highly experienced teachers who have earned their spurs in practice are essential in this regard. Mikrocentrum is CEDEO accredited and guarantees the best quality.

Our course manager is happy to think along with you!

Are you interested in an internal company trajectory? Our training manager Elroy Leijten is happy to visit you without obligation.