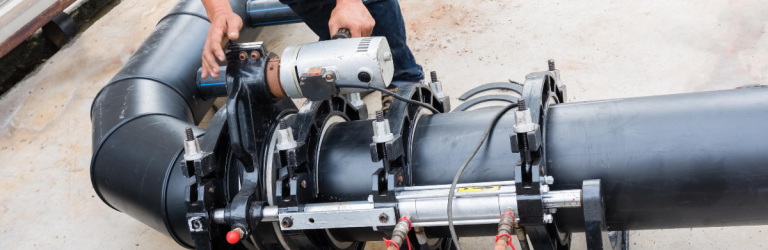

Plastic welding is increasingly chosen for joining certain plastic parts such as pipework, drip trays, shell parts and some industrial products. The practical plastic welding course is always tailor-made, depending on the type of welding process, materials and dimensions.

- Put theory into practice immediately during welding trials

- Experience an efficient work sequence that guarantees quality delivery

- Benefit from independent advice on welding equipment and tools

About the plastic welding course

The market increasingly demands guaranteed or certified quality. This course therefore highlights all aspects and methodologies for solid plastic welding. This includes aspects such as the properties of materials like PVC-C, ABS, HDPE, PPH, PPR and PVDF and their processing. Topics such as health and safety are also covered, as well as other methods of material joining such as gluing.

The following welding methods/materials are covered:

- Hot gas welding, wire welding with tube or fast welding nozzle

- Extrusion welding, continuous or discontinuous

- Butt-welding and fillet-welding in accordance with DVS 2207 and/or NEN 7200

- Socket welding

- Electrofusion welding and saddle welding

- Gluing of plastic pipes

- PVC-C, ABS, HDPE, PPH, PPR, PVDF

Duration

This course is delivered within your company and adapted to your business situation. The great advantage is that welders work in their familiar environment with their own welding equipment and tools. The duration of the course depends on the experience of the welders and the number of welding methods.

Program

Topics

- Material technology

- Material processing

- Welding joints and terminology

- Principles of various welding methods

- Health and safety

- Testing of welds

- Welding sequences

- Welding protocols

- Welding of the various test welds required

Discover the possibilities to organize this course incompany

If you want to train several employees in your company, it is more interesting and cheaper to organize a course at your location. Good coordination to your company-specific situation and the deployment of highly experienced teachers who have earned their spurs in practice are essential in this regard. Mikrocentrum is CEDEO accredited and guarantees the best quality.

Our course manager is happy to think along with you!

Are you interested in an internal company trajectory? Our training manager Barend Blom is happy to visit you without obligation.