When starting up and shutting down extrusion production, it's important to follow established procedures. Specific knowledge of the influence on various process parameters is necessary for optimal throughput and product quality. In the Extrusion 2 course, in addition to the above, there is also a lot of focus on quality systems and statistics.

- Learn the key properties of using additives and fillers

- Gain insight into which parameters can change certain quality aspects

- Avoid unnecessary production downtime

About the Extrusion 2 Course

The Extrusion 2 course is an advanced course that delves deeper into all parameters and their influence on the processing process. Numerous practical examples are provided. The goal is to teach you the consequences of your actions and to develop a correct sequence of working. This will enable you to function more independently and with greater confidence, significantly improving product quality and efficiency.

The course is recognized as an industry training and concludes with a theory exam (NRK diploma).

After completing the course, you will:

- Know how to optimize the use of the extruder and peripheral equipment

- Understand the properties relevant to the processing of thermoplastics

- Understand the structure and operation of components and the extruder itself

- Understand the structure of the extrusion and follow-up processes

- Understand the operation and influence of various parameters on the processes

Program

Product Knowledge

- Chemical terms and concepts of plastics

- Physical concepts of plastics

- Molecular structure of polymers

- Properties and applications of thermoplastics

Environment and Product

- Recycling and reuse of plastics

- Environmentally safe disposal of residues and waste

- Methods of recycling defective products and plastic materials

Quality Management

- Inspection of purchased raw materials

- Definition of quality

- Production control

Equipment Knowledge

- Description of the necessity and definitions of measurement and control technology

- Measurement transducers

- Temperature control

- Dimensioning

- Description of transportation methods

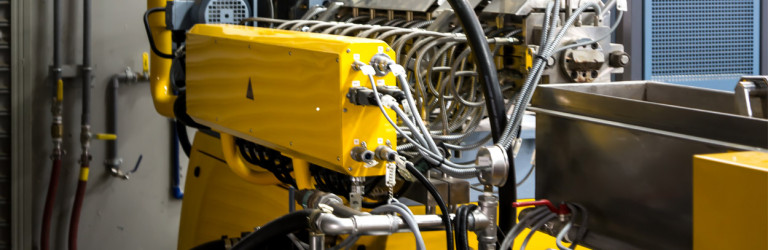

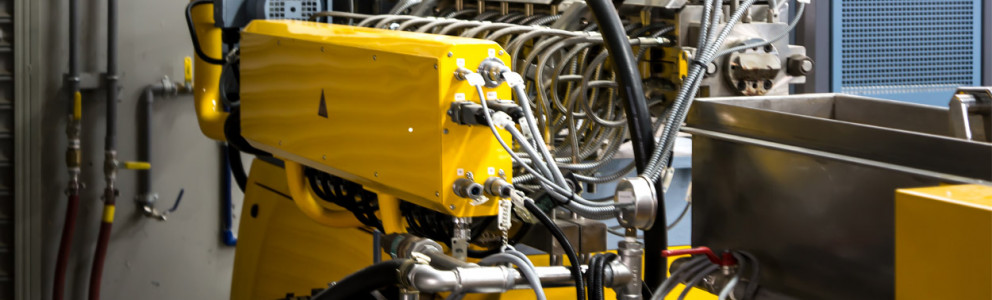

- Operation of the single-screw extruder

- Operation of the twin-screw extruder

- Differences between co-rotating and counter-rotating twin-screw extruders

- Auxiliary equipment

Discover the possibilities to organize this workshop internally within your company

When you want to train multiple employees in your company, it is more interesting and cost-effective to organize a course at your location. Good alignment with your company-specific situation and the use of highly experienced instructors who have earned their stripes in practice is essential here. Mikrocentrum is CEDEO-certified and guarantees the best quality.

Our program manager is happy to think along with you!

Are you interested in this in-company trajectory? Our program manager, Barend Blom, would be happy to visit you without obligation.